Are you torn between the timeless beauty of hardwood floors and the practical realities of modern living? Do concerns about moisture, installation costs, or basement applications make you hesitate to invest in traditional solid hardwood?

Engineered hardwood flooring offers the perfect solution, delivering the authentic look and feel of real wood with enhanced stability, versatility, and often more affordable pricing than solid alternatives.

Credits: @purezawood

Engineered hardwood has revolutionized residential flooring by combining genuine hardwood veneer tops with stable plywood or high-density fiberboard cores. This innovative construction method creates floors that resist moisture and temperature fluctuations better than solid wood while offering installation flexibility impossible with traditional planks.

Whether you’re renovating a basement, updating a kitchen, or installing floors throughout your entire home, engineered hardwood provides practical benefits without compromising the natural beauty that makes wood flooring so desirable.

What Is Engineered Hardwood Flooring?

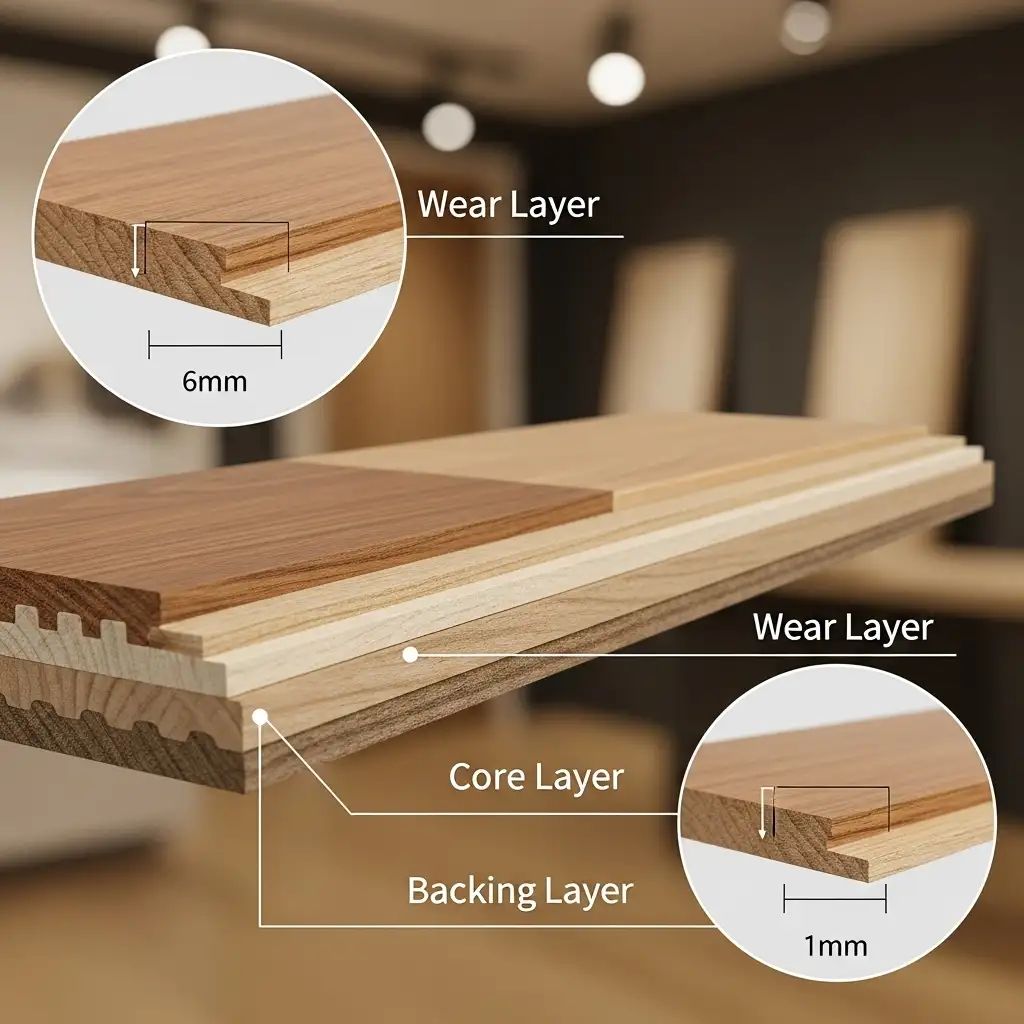

Engineered hardwood consists of multiple layers of wood pressed together, with a top layer of genuine hardwood veneer bonded to a core of plywood or high-density fiberboard. The top wear layer ranges from 1mm to 6mm thick depending on quality and price point, with thicker layers allowing for refinishing just like solid wood.

This cross-grain construction creates dimensional stability that resists warping, cupping, and gapping caused by humidity and temperature changes that plague solid hardwood. The genuine wood top layer means engineered hardwood looks, feels, and even sounds like solid wood underfoot while offering superior performance in challenging environments where traditional hardwood would fail. Read detailed guide on the wood flooring.

Engineered vs. Solid Hardwood: Key Differences

Solid hardwood is milled from a single piece of timber, typically three-quarters of an inch thick, offering maximum refinishing potential but limited installation flexibility. Engineered hardwood uses layered construction with genuine wood veneer on top, providing authentic appearance with superior moisture resistance and dimensional stability that solid wood cannot match. You can also learn our detail guide on faux wood ceiling.

While solid hardwood can only be nailed over wooden subfloors, engineered options work with multiple installation methods including floating, gluing, or nailing over various substrates including concrete. The core construction makes engineered flooring suitable for basements, over radiant heating, and in areas with fluctuating humidity where solid wood would warp or fail.

Where Engineered Hardwood Excels

Basement Installations

Engineered hardwood works beautifully in basements where solid hardwood would warp and fail due to concrete moisture and temperature fluctuations. The stable core construction resists moisture infiltration while the genuine wood top provides warmth and beauty that transforms below-grade spaces into inviting living areas. This makes engineered flooring the only real wood option for basement family rooms, bedrooms, or entertainment spaces where authentic wood character matters without the risk of damage. Check our brilliant basement ceiling ideas for complete basement design inspiration.

Over Radiant Heating Systems

Credits: @kaplanflooringcanada

Engineered hardwood’s layered construction allows heat to transfer through the floor more efficiently than solid wood while resisting warping from temperature changes. The stable core prevents cupping and gapping that solid hardwood experiences when installed over radiant systems, making it the preferred choice for modern energy-efficient homes. Always verify specific products are rated for radiant heating applications and follow manufacturer guidelines for maximum temperature settings to ensure longevity and maintain warranties through proper use.

Kitchen and High-Traffic Areas

Kitchens benefit from engineered hardwood’s superior moisture resistance compared to solid wood, handling spills and humidity from cooking better than traditional planks. The stable construction maintains consistent appearance despite temperature fluctuations from appliances and frequent traffic patterns that would stress solid wood. Quality engineered flooring with thick wear layers provides durability that withstands daily family life while maintaining the warm, natural aesthetic that makes kitchens feel welcoming. Explore our kitchen remodel ideas and kitchen renovation ideas for complete kitchen design.

Understanding Wear Layer Thickness

The wear layer thickness determines how many times engineered flooring can be refinished and ultimately its lifespan. Products with 6mm wear layers can be sanded and refinished multiple times like solid hardwood, offering decades of service. Mid-range options with 3-4mm wear layers allow one or two refinishing cycles, extending lifespan beyond initial finish wear. Budget products with 1-2mm veneers cannot be refinished and must be replaced when surfaces show significant wear, though they still offer years of service in low-traffic areas. Thicker wear layers cost more initially but provide better long-term value through extended lifespan and refinishing potential.

Core Construction Types

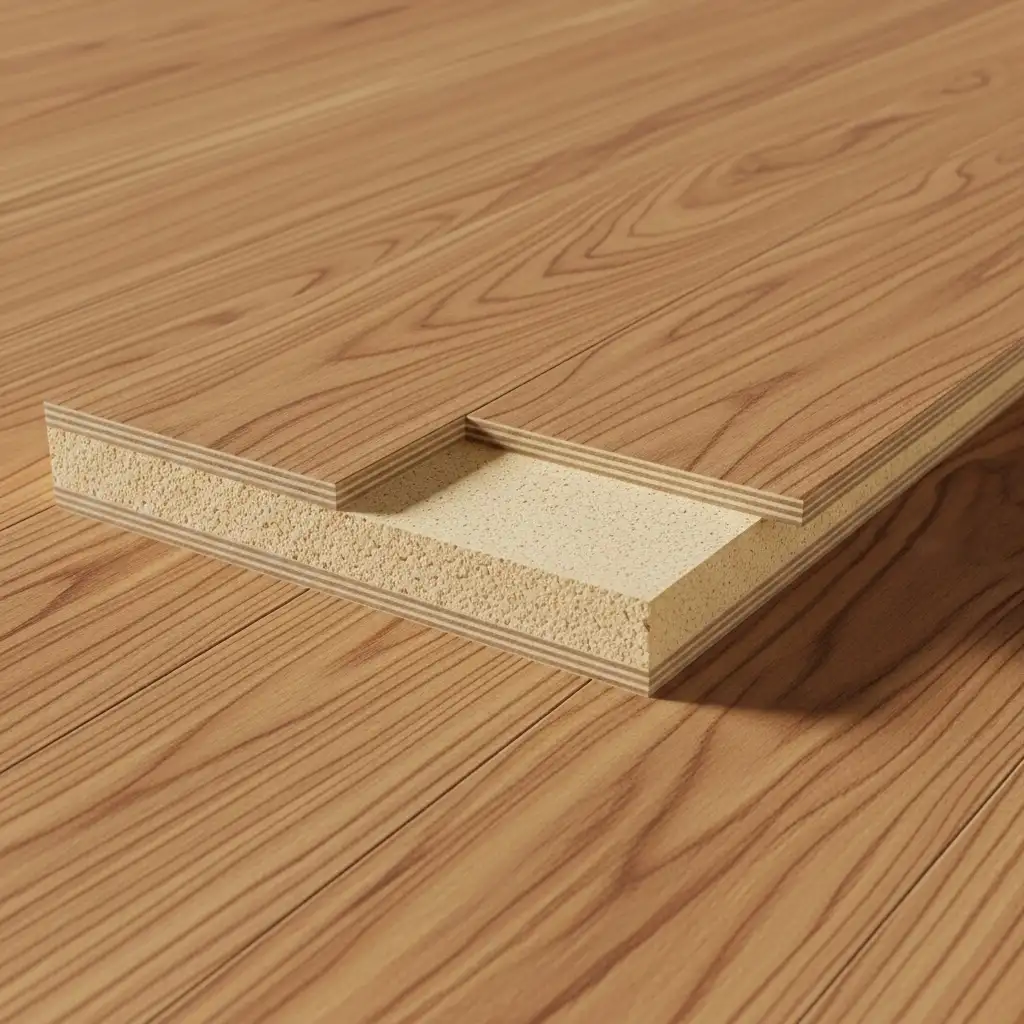

Plywood Core

Plywood cores use multiple thin layers of wood arranged perpendicular to each other, creating exceptional dimensional stability. This traditional core construction offers superior nail-holding strength for nail-down installations while resisting moisture better than solid wood. Plywood cores tend to be more expensive but provide premium stability and durability that justify the investment in high-quality installations where performance matters most over decades of use.

High-Density Fiberboard (HDF) Core

HDF cores compress wood fibers under high pressure, creating dense, uniform cores that resist moisture while maintaining stability. This engineered core costs less than plywood while still providing good performance in residential applications. HDF cores work particularly well in floating floor installations where the density provides solid feel underfoot, though they offer less nail-holding strength than plywood for nail-down applications in certain circumstances.

Installation Methods for Engineered Hardwood

Floating Floor Installation

Floating installation connects planks to each other rather than the subfloor, creating a unified floor that “floats” over underlayment. Click-lock or tongue-and-groove systems glued along edges hold planks together while allowing the entire floor to expand and contract as needed. This DIY-friendly method requires no specialized tools beyond basic saws and works over any level subfloor including concrete, existing vinyl, or even ceramic tile with proper underlayment. Floating floors install quickly, with rooms often completed in a day, and floors are immediately usable after completion.

Glue-Down Installation

Glue-down installation uses specialized flooring adhesive to bond planks directly to subfloors, suitable for both wood and concrete substrates. This method works well with engineered hardwood, particularly in basement installations or over radiant heating where dimensional stability is crucial. The adhesive creates a solid connection that eliminates hollow sounds while accommodating the flexibility of engineered products better than nailed installations. Proper glue-down installation requires meticulous subfloor preparation, ensuring surfaces are level, clean, and moisture-free for lasting results.

Nail-Down Installation

Traditional nail-down installation remains an option for engineered hardwood over wooden subfloors, using pneumatic flooring nailers to drive cleats through plank tongues. This method works best with thicker engineered products featuring plywood cores that hold fasteners securely. Nail-down provides permanent installation that maximizes floor lifespan and refinishing potential while providing excellent stability and minimal hollow sound when walking. The process requires solid wooden subfloors and experience with flooring nailers for professional results.

Popular Wood Species for Engineered Flooring

Oak Engineered Hardwood

Credits: @thelemonterrace

Oak remains the most popular engineered hardwood choice, available in red and white varieties with distinctive grain patterns. Red oak features warm, pinkish undertones with prominent grain, while white oak offers cooler tones with subtler graining that suits contemporary designs. Both species offer excellent durability and accept stains beautifully, allowing for extensive color customization from natural tones to dramatic grays. Oak’s widespread availability keeps costs moderate while delivering timeless appeal that never goes out of style.

Maple Engineered Flooring

Credits: @elliottbrotherswoodworks

Maple engineered hardwood offers smooth, consistent grain with subtle color variations ranging from nearly white to light amber tones. The light, uniform appearance creates clean, contemporary looks that brighten spaces and complement modern design schemes beautifully. Maple’s hardness provides excellent resistance to dents and scratches in busy households, making it practical for families with children and pets. The tight grain makes maple less receptive to dramatic staining, so most installations feature natural or lightly stained finishes.

Walnut and Exotic Species

Credits: @poaflooring_zim

Walnut engineered flooring delivers sophisticated, chocolate-brown tones with rich grain patterns that add instant luxury to any space. Exotic species like Brazilian cherry, acacia, or bamboo offer unique colors and extreme hardness unavailable in domestic woods, creating distinctive floors with character. These premium options cost more than oak or maple but provide one-of-a-kind aesthetics that justify the investment in high-end installations. Always verify exotic species carry Forest Stewardship Council (FSC) certification indicating sustainable harvesting practices.

Finish Options and Surface Treatments

Pre-finished vs. Unfinished

Pre-finished engineered hardwood arrives with factory-applied finishes cured under controlled conditions using UV light or industrial processes. These durable surfaces resist scratches and wear better than site-applied finishes while allowing immediate use after installation. Unfinished engineered flooring allows for custom stain colors perfectly matched to your vision with seamless integration between planks, though it requires several days for on-site finishing and curing that makes spaces unusable during the process.

Surface Texture Varieties

Smooth surfaces create formal, traditional aesthetics with reflective shine that showcases wood grain clearly. Hand-scraped textures add rustic character with irregular surfaces that hide wear and create authentic aged appearances. Wire-brushed finishes emphasize grain patterns by removing soft wood between harder growth rings, creating subtle texture with contemporary appeal. Distressed finishes feature intentional dings, scrapes, and color variation that deliver farmhouse charm while disguising future damage within the overall weathered aesthetic. For rustic design inspiration, visit our warm rustic living room ideas.

Width and Plank Length Considerations

Plank width dramatically impacts room perception and aesthetic character. Traditional strip flooring measuring 2-3 inches wide creates busy, linear patterns that suit smaller spaces and traditional design schemes. Wide planks ranging from 5-7 inches create contemporary, spacious feelings while showcasing dramatic grain patterns and reducing visible seams for cleaner sight lines. Longer planks minimize end joints, creating uninterrupted flow that enhances sophistication and makes rooms feel larger. Consider room size when selecting dimensions – narrow planks can make small spaces feel cramped, while extra-wide planks may overwhelm compact rooms despite their contemporary appeal.

Color Selection and Trends

Natural and Light Tones

Credits: @pacifichardwood

Light engineered hardwood in natural, blonde, or whitewashed finishes reflects maximum light, making spaces feel larger and airier while hiding dust better than dark floors. These versatile neutrals complement any design style from Scandinavian minimalism to coastal farmhouse, providing clean backdrops that allow furniture and decor to shine. Light floors show dark pet hair and some scratches more readily but remain popular for their brightening effect and timeless appeal that transcends trends.

Medium Brown Tones

Medium browns offer practical middle ground, providing warmth without extreme maintenance challenges while suiting traditional and transitional design schemes. These classic tones hide dirt and wear better than very light or very dark alternatives, making them ideal for busy families seeking low-maintenance beauty. Medium browns pair well with most furniture colors and design styles, offering versatility that ensures lasting appeal through changing decor preferences over decades.

Gray and Contemporary Finishes

Credits: @royal_sequoia_flooring

Gray-toned engineered hardwood has surged in popularity, offering sophisticated neutrality that feels more contemporary than traditional browns. These modern finishes range from soft gray-washed to dramatic charcoal, providing options for every design preference. Gray floors complement both warm and cool color palettes while creating contemporary aesthetics that feel current without being trendy. The color hides dust and light scratches reasonably well while providing distinctive character that makes spaces feel designed and intentional.

Dark and Dramatic Choices

Dark engineered hardwood in espresso, walnut, or ebony tones creates intimate, sophisticated atmospheres with formal elegance. These dramatic finishes make rooms feel smaller while showing every speck of dust and light-colored pet hair, requiring more frequent cleaning. Dark floors provide stunning contrast against white walls and light furniture, creating bold statements that work beautifully in formal dining rooms or master bedrooms. The rich tones add luxury and drama that justify maintenance requirements for homeowners seeking high-impact design. Explore our black and white bedroom ideas and black and grey bedroom ideas for dramatic color schemes.

Installation Patterns Beyond Standard

Herringbone Pattern

Herringbone installation arranges planks in distinctive zigzag patterns that create sophisticated, high-end appearances perfect for formal spaces. This traditional pattern requires more material due to waste, skilled installation for precise angles, and higher costs, but delivers timeless elegance impossible with standard layouts. Herringbone works beautifully in entryways, dining rooms, or any space deserving architectural distinction. See our herringbone tile bathroom ideas and herringbone backsplash guide for pattern inspiration.

Chevron and Diagonal Layouts

Chevron patterns feature planks cut at precise angles meeting in continuous V-shapes, creating even more dramatic visual impact than herringbone. Diagonal installation adds dynamic energy to square rooms while making spaces appear larger through unconventional sight lines. Both patterns require significant material waste, skilled installation, and increased costs but create distinctive floors that become conversation pieces and architectural features rather than simple surfaces.

Maintenance and Long-Term Care

Engineered hardwood requires simple maintenance to preserve beauty for decades of service. Sweep or vacuum daily to remove abrasive dirt particles that gradually dull finishes and create micro-scratches. Clean spills immediately with barely damp cloths to prevent water penetration and staining. Use manufacturer-approved wood floor cleaners rather than harsh chemicals, vinegar, or excessive water that can damage finishes or seep between planks. Place felt pads under furniture legs to prevent scratches and use area rugs in high-traffic zones to protect surfaces from premature wear.

Cost Considerations and Budgeting

Engineered hardwood typically costs $3-$12 per square foot for materials depending on species, wear layer thickness, and finish quality. Installation adds $3-$8 per square foot for professional work, though DIY floating installations eliminate labor costs entirely. A 500 square foot room might cost $3,000-$10,000 total for materials and installation. While more expensive than laminate or vinyl, engineered hardwood offers genuine wood beauty and better longevity that justifies the investment through decades of service and enhanced home value. For budget-friendly alternatives, explore our herringbone laminate flooring options.

Environmental and Sustainability Factors

Engineered hardwood uses less premium hardwood per plank than solid alternatives, making it more environmentally efficient while preserving old-growth forests. The core layers utilize fast-growing wood species or recycled materials, reducing environmental impact. Look for products with Forest Stewardship Council (FSC) certification indicating responsible harvesting practices. Many manufacturers now offer low-VOC or zero-VOC finishes that improve indoor air quality by eliminating harmful off-gassing chemicals that traditional finishes release for months after installation.

Common Problems and Solutions

Gapping Between Planks

Gaps develop when humidity drops and wood contracts, particularly in winter when indoor heating reduces moisture. Maintain consistent indoor humidity between 35-55% using humidifiers to minimize seasonal movement. Small gaps are normal and close when humidity increases, but persistent large gaps may indicate installation issues or inadequate acclimation before installation that requires professional assessment.

Cupping and Warping

Cupping occurs when plank edges rise higher than centers due to moisture absorption from below, while warping indicates more severe moisture damage. These issues often result from water leaks, improper installation over concrete without moisture barriers, or extreme humidity exposure. Address moisture sources immediately and consult professionals about repair options that may include drying, sanding, or replacement depending on damage severity.

Finish Wear and Scratches

Surface scratches and finish wear are inevitable with use but can be minimized through proper maintenance including felt pads, area rugs, and regular cleaning. Minor scratches often disappear with wood floor refresher products or touch-up markers. When finish wear becomes widespread, engineered floors with thick wear layers can be professionally refinished, restoring like-new appearance without full replacement costs.

Frequently Asked Questions

Is engineered hardwood better than solid hardwood?

Engineered hardwood isn’t necessarily “better” but offers different advantages including superior moisture resistance, installation versatility, and lower cost while maintaining genuine wood beauty. It works in basements, over concrete, and over radiant heating where solid wood fails. Solid hardwood offers maximum refinishing potential and traditional construction some prefer. Choose based on your specific installation location, budget, and performance requirements rather than assuming one is universally superior to the other.

Can engineered hardwood be refinished?

Quality engineered hardwood with wear layers 3mm or thicker can be refinished one or more times depending on veneer thickness. Products with 6mm wear layers refinish multiple times like solid wood, while 3-4mm layers allow one or two sandings. Thin veneers under 2mm cannot be refinished and must be replaced when surfaces show significant wear. Always verify wear layer thickness before purchasing if refinishing potential matters for your long-term plans.

How long does engineered hardwood last?

High-quality engineered hardwood with thick wear layers lasts 30-50 years with proper maintenance, comparable to solid hardwood. Products with thinner veneers may last 15-25 years depending on traffic and care. Lifespan depends on wear layer thickness, finish quality, installation method, maintenance practices, and traffic levels. Quality engineered flooring from reputable manufacturers represents a permanent installation that serves families for decades when properly maintained through regular cleaning and protection.

Is engineered hardwood good for basements?

Engineered hardwood is the only real wood option suitable for basements due to its superior moisture resistance and dimensional stability. The layered construction resists warping and cupping from concrete moisture that would destroy solid hardwood. Always ensure basements have proper moisture barriers, adequate dehumidification, and no active water issues before installing any wood product. When conditions are appropriate, engineered hardwood transforms basements into warm, inviting living spaces with authentic wood character impossible with other flooring types.

Conclusion: Making the Smart Flooring Choice

Engineered hardwood flooring represents the evolution of traditional wood floors, combining timeless natural beauty with modern performance that suits contemporary lifestyles. The layered construction delivers genuine hardwood aesthetics with enhanced stability, moisture resistance, and installation flexibility that solid wood cannot match, making it ideal for basements, kitchens, and modern homes with radiant heating or concrete slabs.

When selecting engineered hardwood, prioritize quality indicators like thick wear layers, reputable manufacturers, and appropriate core construction for your installation method. Consider your specific room conditions, traffic patterns, and long-term refinishing goals when choosing products and finishes. With proper selection and maintenance, engineered hardwood provides decades of beautiful, durable flooring that enhances home value while creating warm, inviting spaces your family will love.

Ready to explore complementary design elements? Check our guides including guide to herringbone tile floors, home interior design ideas, small living room ideas, and bedroom ideas for couples for complete home design inspiration. Whether you’re installing floors in a single room or throughout your entire home, engineered hardwood offers the perfect balance of beauty, performance, and value that makes it the smart choice for modern living.